Press Fit Pressure Calculator

Press fit is important in mechanical assembly and engineering. It helps you know how much force is needed to push one part into another to join them securely. This matters for things like bearings, bushings, gears, and structural parts.

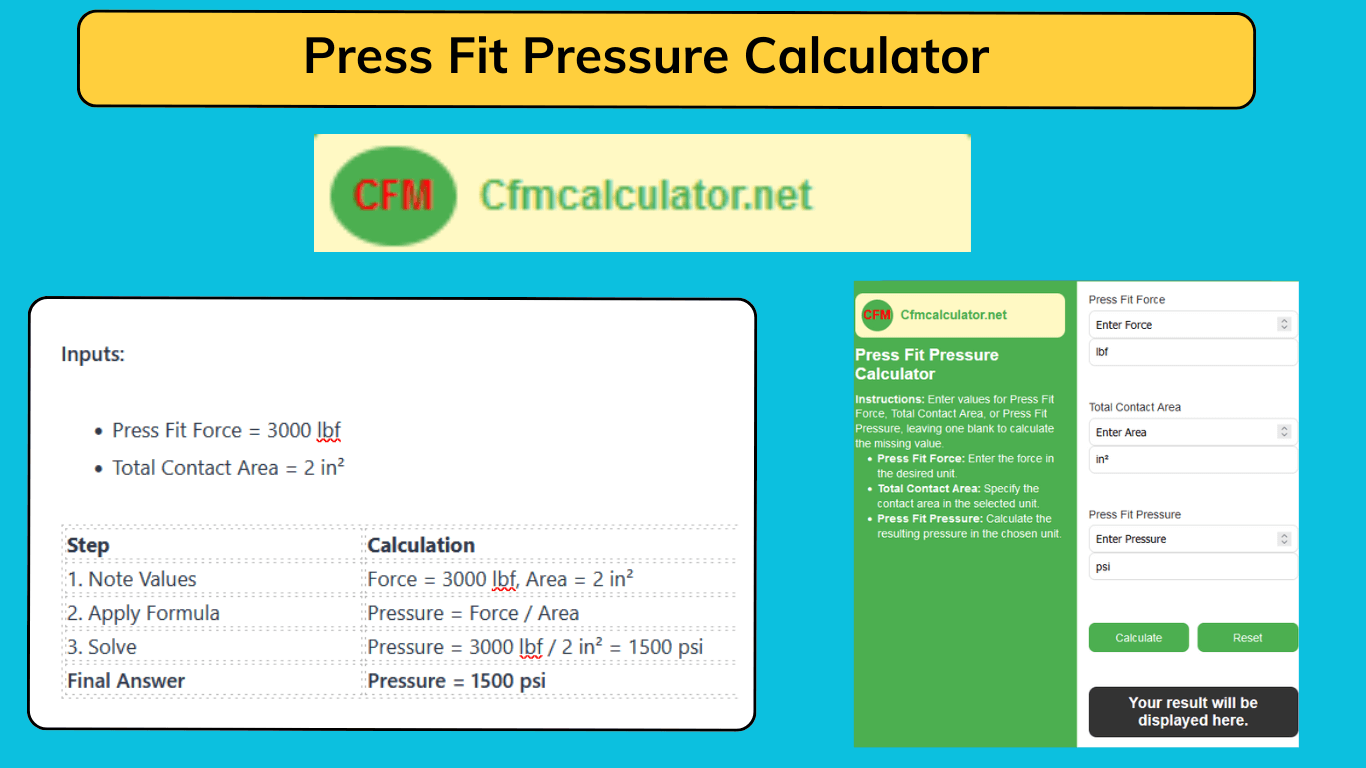

To meet your needs, the tool can calculate pressure from a press-fit force and area or determine the area from force and pressure. Just leave one field empty for the value you want to calculate.

🔧 Press Fit Pressure Calculator

How to Calculate Press Fit Pressure

The formula to find out press fit pressure is:

Example

If an engineer is fitting a steel gear onto a shaft in a car’s transmission, he needs enough pressure to keep the gear from slipping when the engine turns. For that, he’ll figure out the right force to avoid damage and keep everything working smoothly.

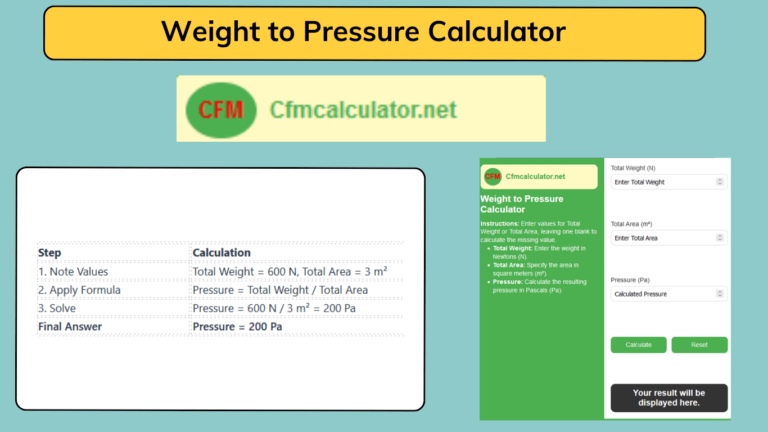

Calculation Steps:

- Press Fit Force: 5000 N

- Total Contact Area: 10 cm²

✅ The press fit pressure is 50 bar (or 5 MPa).

💡 Tip: Use our tool and improve the reliability of your assembled components and avoid mechanical failure.